Inspection & Testing

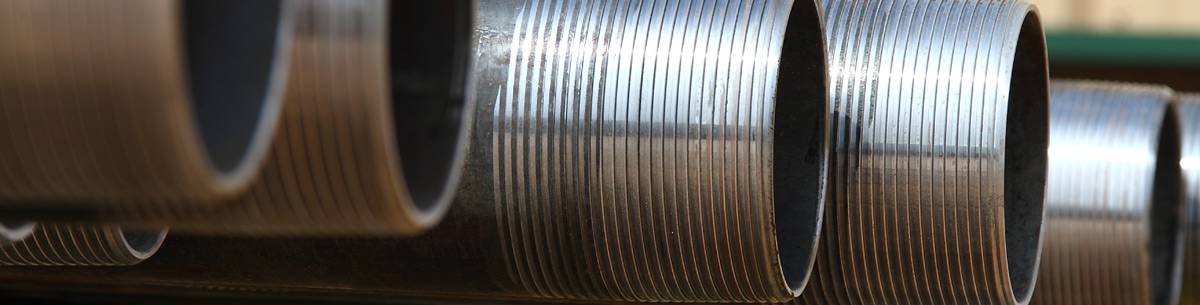

Prior to inspection and testing services, all used pipe has been OD brushed and cleaned the entire length of the joint to ensure accurate inspection. Cleaning machines are also equipped to air rattle ID of tubing as required to properly determine condition.

ElectroMagnetic Inspection

FTTS operates an ND T-6000 and New Tech 554 EMI units for NDT inspection of tubing and casing from 2 3/8” OD tubing through 13 3/8” OD casing.

Special End Area Inspection

In conjunction with the ND T-6000 EMI unit, we can perform a ‘wet mag’ end area inspection of all pipe utilizing an Aeroplata ML TIED- 440CR unit to detect any flaws prior to the EMI inspection. This unit is installed in line with our ND T-6000 unt.

hydroydrostatic Testing

FTTS operates three hydrostatic testing units, capable of pressure testing OC TG with API connections from 2 3/8” OD through 7” OD. Any connection leaks can be identified and marked for possible repair, and re-tested to ensure pressure integrity.

Contact Flake

If you are interested in learning more about Flake Tompkins Tubular Services, contact us at (432) 682-3569 or fill out our contact form.